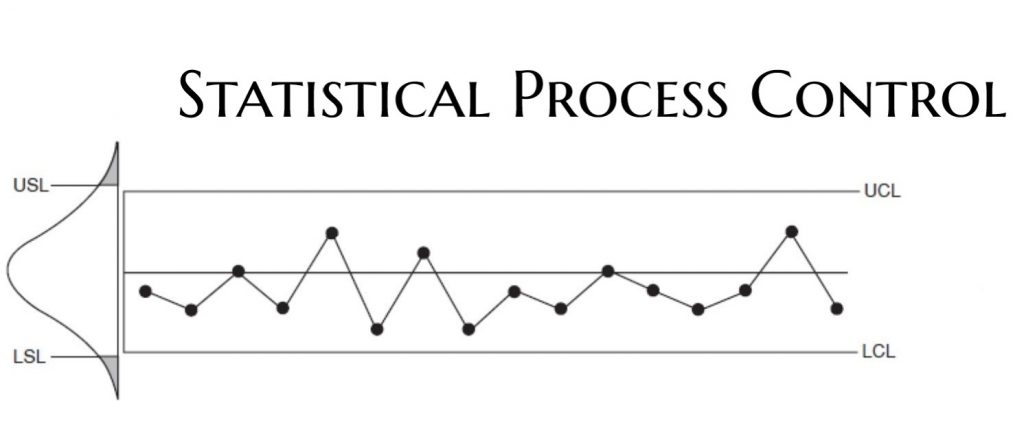

Statistical Process Control is a preventive control method which helps us following the production processes continuously and taking precautions before the failure occurs. Otherwise there would be non-conforming productions which would need to be re-worked.

SPC helps planning and directioning of production resources. The predictability of variance and process quality level makes us foresee the re-working resource needed.

On the other hand, long term SPC analysis helps us see some of the characteristic process tendencies such as tool wear-out periods.

In short, SPC is the most economical methodology ensuring that the customer expectations are always satisfied by simultaneously minimizing the production costs.

Production and Quality responsibles get your appointment for a one day SPC training soon.