Today lives of some of the durable goods are determined by their technology life cycles. This is 5 years for computers and 10 years for home appliances.

On the other hand we expect that the materials used in construction of our buildings should have much longer lives despite the daunting effects of wind, sun and the rain.

The manufacturers should have an idea about the durability of their products under the environmental conditions which they work in. Life tests are a way of measuring this and getting to an estimation.

The perceived quality of the product during its purchase doesn’t necessarily imply about the life of that product. Early breakdowns and broken products return as economical loss and reliability problem to the customers.

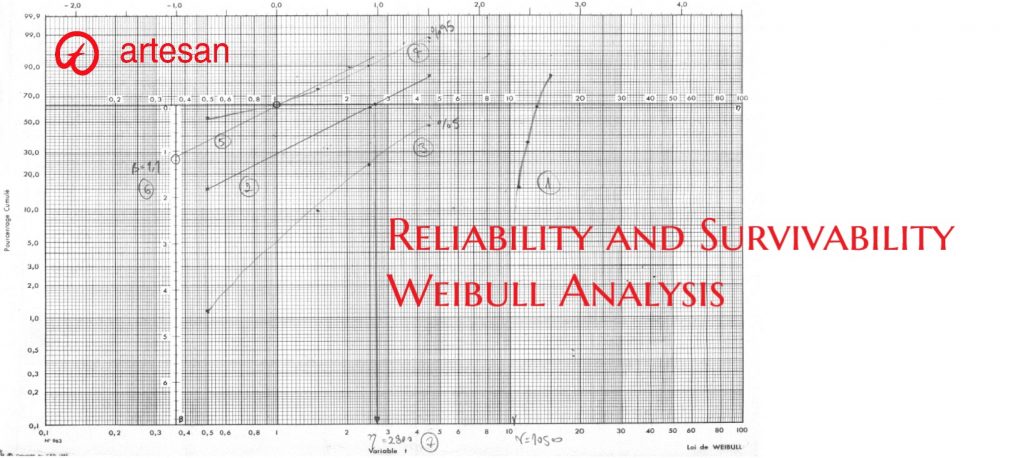

With the help of Weibull Analysis you’ll be able to use the usually neglected outcomes of life cycle tests in the estimation of reliability (the probability that a product would work as long as a certain number of cycles or the percentage of products which will withstand till that cycle) and durability (the percentage of products which will survive after a certain cycle). Moreover you’ll get answers to your following questions :

- How long will the product work until its breakdown? What is its life?

- What is the duration of that the 50%, 75%, 95% of the products remain intact?

- How many products would be broken within its warranty period?

- Can I give longer warranty periods to my products compared to my competitors? How much does it cost to me?

- Is my product overdesigned? Should I turn back and review my design? Does that bring gain or loss?

Get your appointment for the training soon.